Overview

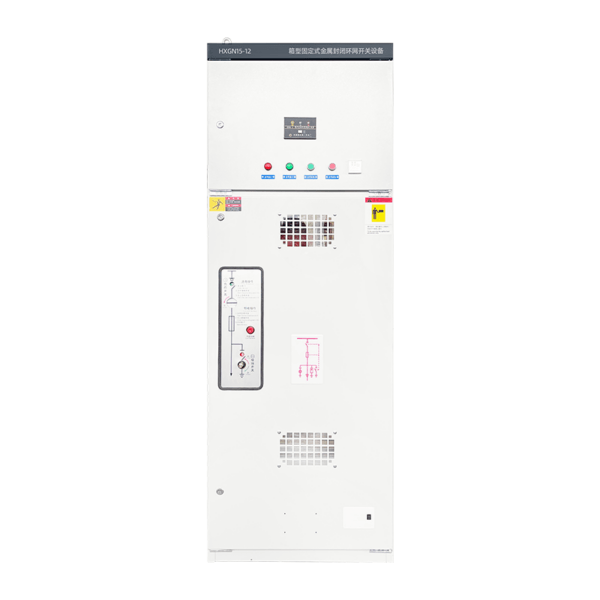

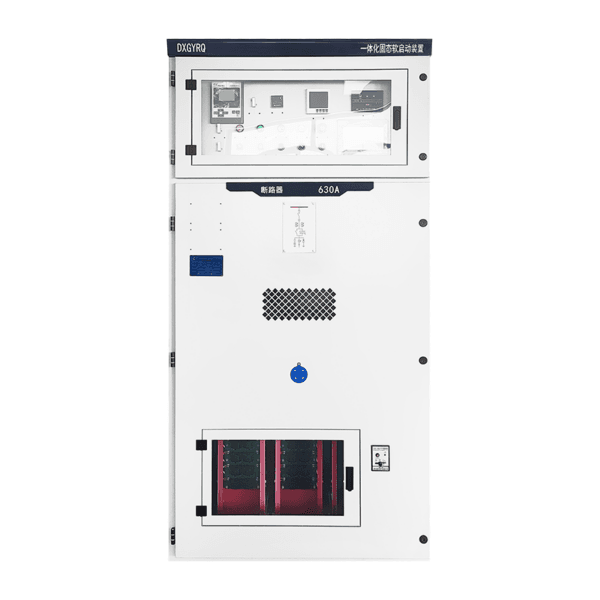

FG3000 series medium voltage variable frequency drive (VFD) cabinet is designed for efficient, precise, and reliable speed control of high-power AC motors. Based on advanced vector control technology, the system supports both synchronous (including permanent magnet synchronous) and asynchronous motors. It integrates control, power, transformer, and switching units into a compact modular structure for easy on-site installation and maintenance.

If you need detailed parameters, please check the pdf document above or contact us.

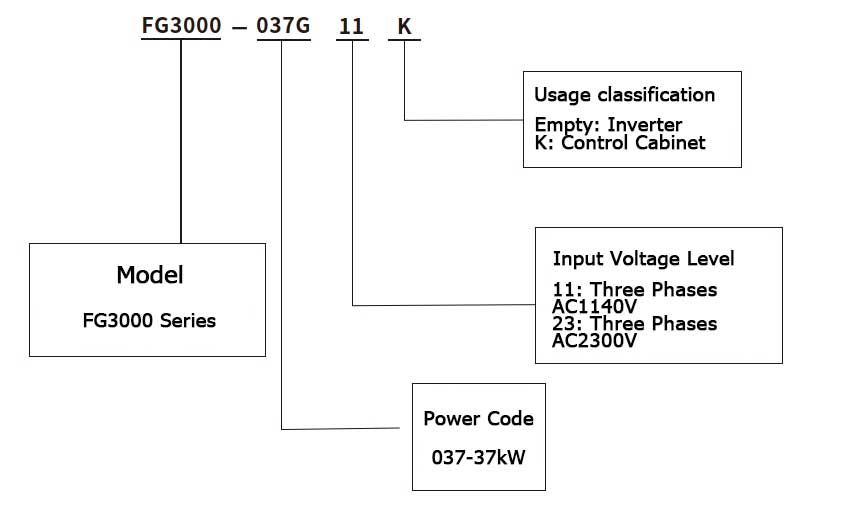

Model and meaning

Technical Specification

Model Description

| Rated Power Voltage | Model | Rated Output Power(kW) | Rated Output Current(A) |

| Three Phases AC 1140V | FG3000-034G-11 | 37 | 23 |

| FG3000-045G-11 | 45 | 28 | |

| FG3000-055G-11 | 55 | 34 | |

| FG3000-075G-11 | 75 | 48 | |

| Three Phases AC 2300V | FG3000-125G-23 | 125 | 39 |

| FG3000-200G-23 | 200 | 62 |

Technical Characteristics

| Item | Standard Specification | |

| Input | Rated Power Voltage | 3-Phase 1140V, 2300V, 50-60Hz ± 5%, voltage imbalance < 3% |

| Output | Rated Voltage | The maximum output voltage is the same as the input power supply voltage |

| Rated Current | 100% rated current continuous | |

| Overload Capacity | 150% rated current for 1 minute | |

| 180% rated current for 2 seconds | ||

| Output Frequency | 0 ~ 600Hz, can be set | |

| Main Control Function | Control Method | WVF (optimized PWM and standard PWM, can be set), vector control, V/F control |

| Frequency Resolution | Digital setting: 0.01Hz | |

| Startup Frequency | 0-10Hz | |

| Torque boost | Torque increase 0.0%~ 20.0% | |

| V/F Curve | Wasp Five methods: constant torque V/F curve, one user-defined multi-segment V/F curve method, and three downturns Moment characteristic curve method (2.0, 1.7, and 1.3) | |

| Acceleration and Deceleration Curve | Two ways: straight-line acceleration and deceleration, S-curve acceleration and deceleration; two acceleration and deceleration times, the longest time is 3000S | |

| DC Braking | Stop DC braking starting frequency: 0~ 15.00Hz Braking time: 0~ 60.0 seconds Braking current: 0~ 150% | |

| Multi-speed operation | Multi-speed operation via built-in PLC or control terminals | |

| Automatic Voltage Regulation (AVR) | When the grid voltage changes by 10%, maintain the output voltage constant | |

| Automatic Energy-saving Operation | According to the load situation, automatically optimize the V/F curve to achieve energy-saving operation | |

| Communication function | It has RS485 standard communication interface and supports MODBUS communication protocol. | |

| Run Command Channel | LED keyboard, control terminal, serial port (RS485) | |

| Frequency Setting Channel | LED keyboard analog potentiometer, LED keyboard key ‘▲’ , Key ‘▼’、function code, given number, serial port, terminal UP/DOWN, analog voltage, analog current, combination given | |

| Input Dunction | Digital Input Channel | 2-Channel on-stop control terminals, 6-channel programmable digital input |

| Analog Input Channel | 2-Channel on-stop control terminals, 6-channel programmable digital input | |

| Output Function | Digital Output Channel | 2 open collector outputs, 2 relay outputs |

| Analog Output Channel | 2 channels of analog signal output: 2 channels of 0~ 10V/0/4~ 20mA can be switched | |

| Operation Panel | LED digital display | Can display or set frequency converter related parameters |

| Protection Function | Provide multiple protection functions: short circuit, overcurrent, overload, underload, overvoltage, phase loss, overheating, external failure, PID feedback disconnection, 485 disconnection and other protection functions | |

| Accessories | Touch screen, iron room | |

| Environment | Place of Use | Indoor, free from direct sunlight, no dust, corrosive gases, oil mist, water vapor, etc |

| Hypo Altitude | Less than 1000 meters (derating is required when higher than 1000 meters) | |

| Ambient Temperature | —10°C~+40°C | |

| Humidity | Less than 90% RH, no condensation | |

| Vibration | Less than 5.9 m/sec2 (0.6G) | |

| Storage Temperature | —20°C~+60°C | |

| Structure | Protection Level | IP20 |

| Cooling Method | Forced air cooling | |

| Installation Method | Wall mounted or floor mounted | |