Overview

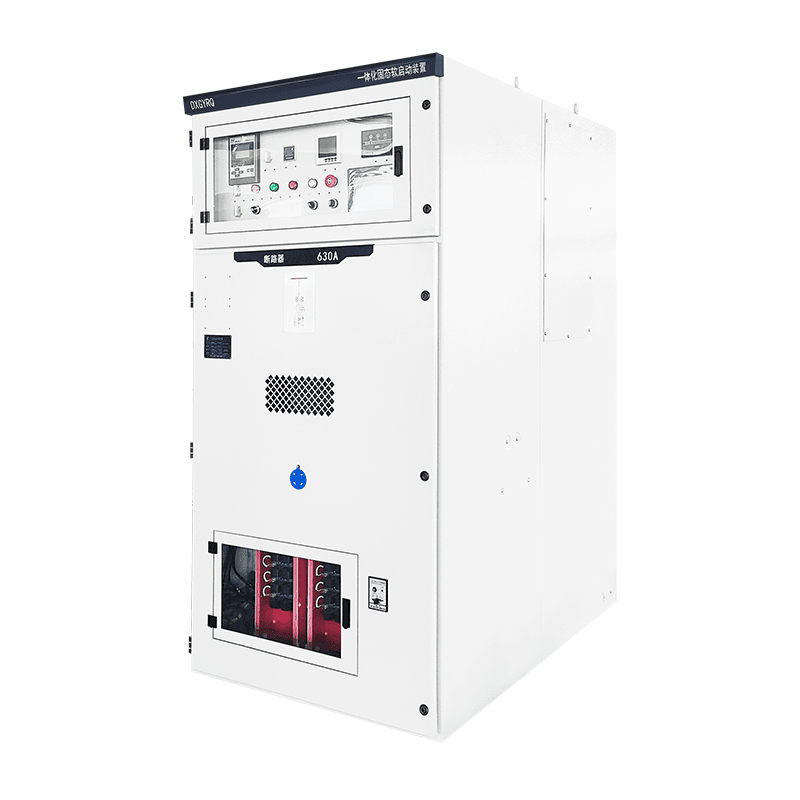

The Medium Voltage Variable Frequency Drive (VFD) Cabinet is a high-performance motor control solution designed for 3kV to 11kV motors, typically used in applications such as fans, pumps, compressors, and other heavy-duty equipment. It enables soft start and variable speed control, improving energy efficiency, reducing mechanical stress, and minimizing grid impact during motor start-up.

This system integrates a medium voltage inverter, isolation transformer, protection module, cooling system, and a user-friendly HMI interface within a compact, modular enclosure. It features comprehensive protections including overvoltage, overcurrent, overheating, phase loss, and ground fault detection.

If you need detailed parameters, please check the pdf document above or contact us.

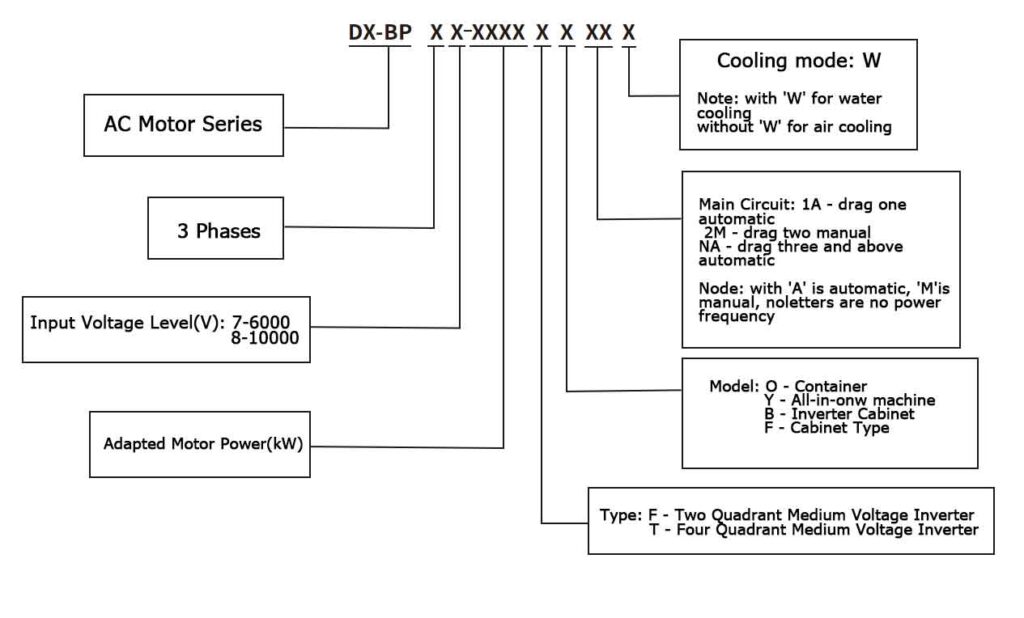

Model and meaning

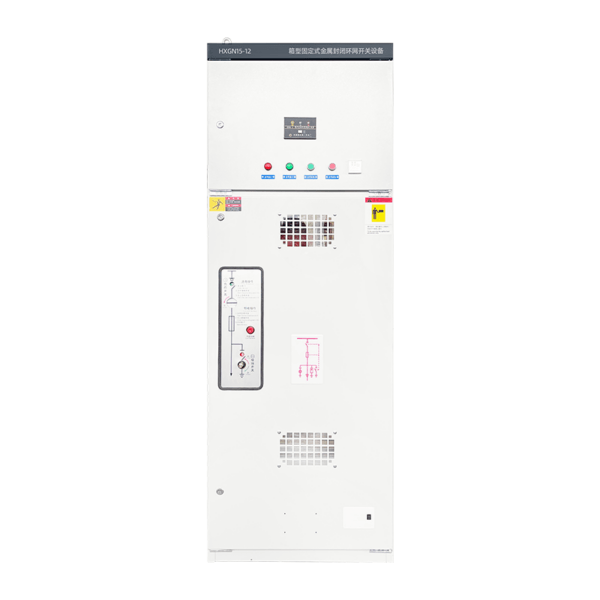

G7 Ordinary Series Medium Voltage Inverter

- Forced Air Cooling

- Designed on a two-/four-quadrant drive platform compatible with synchronous (including PMSMs) and asynchronous motors, the unit features sealed modular construction for improved manufacturing efficiency and reliability.

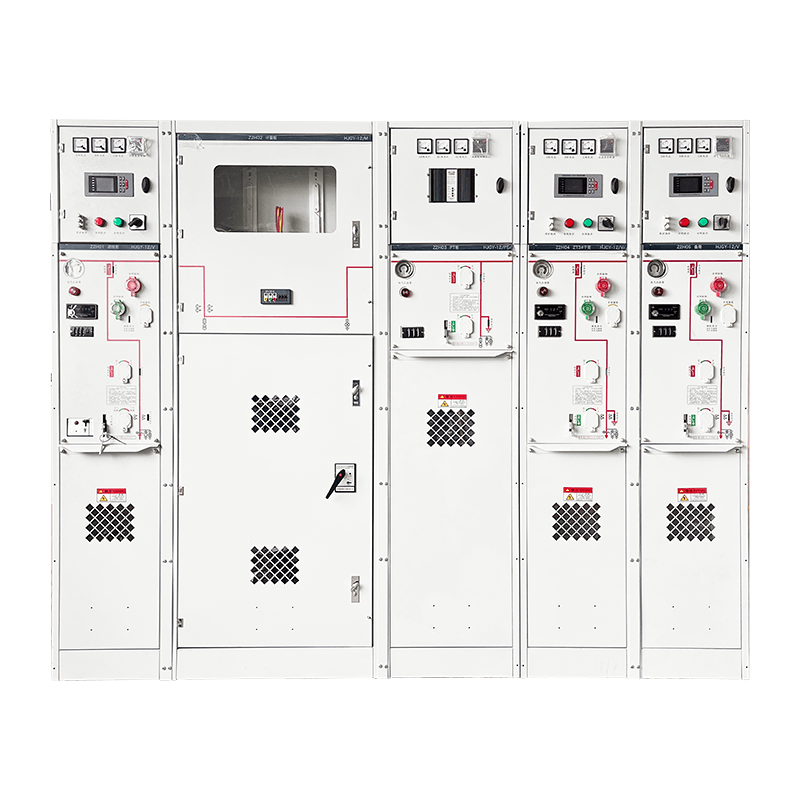

G7 All-in-one Series Medium Voltage Inverter

- Forced Air Cooling

- The system adopts a two-quadrant drive platform compatible with synchronous (including PMSM) and asynchronous motors, integrating the control, power, transformer, and switching cabinets into one complete unit for easy on-site installation.

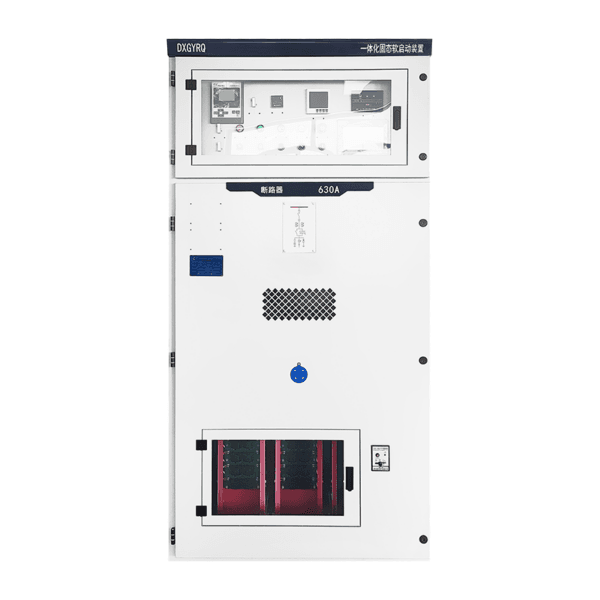

G7 Water Cooling Series Migh Voltage Inverter

- Water Cooling

- The system is designed on a two-quadrant drive platform compatible with synchronous (including PMSM) and asynchronous motors. It utilizes reliable high-power electronic components and an efficient water-cooling system, delivering high power density and excellent adaptability to harsh environments.

Technical Specification

| Model | DX-BP37/38-F | DX-BP37/38-T | |

| Motor Power(kW) | 200-20000(Selection is based on 4-pole motor parameters; for motors with 6 to 12 poles, choose models according to operating current.) | 200-3250(Selection is based on 4-pole motor parameters; for motors with 6 to 12 poles, choose models according to operating current.) | |

| Output | Rated Power(kW) | 200-20000 | 200-3250 |

| Rated Current(A) | Motor operating current at rated voltage | Motor operating current at rated voltage | |

| Overload Capacity | 105% continuous | 105% continuous. | |

| 130% allow 1 minute | 130% allow 1 minute | ||

| 150% allow 3 seconds | 150% allow 3 seconds | ||

| Output Voltage(kV) | Three Phases: 0-6 (0-10) | ||

| Waveform | Multiplexed SPWM sine wave | ||

| Input | Phase,Frequency,Voltage | Three Phases, 50Hz/60Hz, 6kV(10kV) | |

| Allowed to Fuctuate | Voltage: -10%~ + 10%, Frequency: ±5%, -10%~ 35% Derating Continuous operation | ||

| Basic performance | Start Frequency | 0-10Hz can be set | |

| Precision | Analog setting: 0.3% of the maximum frequency setting (25 ± 10 ° C) or less

Digital setting: less than 0.02% of the maximum frequency setting value (-10~ + 50 ° C) |

||

| Resolution | Analog setting: one thousandth of the maximum frequency setting value

Digital setting: 0.01Hz (below 99.99Hz), 0.1Hz (above 100Hz) |

||

| Efficiency | >98%, at rated output | ||

| Power Factor | >0.95 | ||

| control | Acceleration and Deceleration Time | 0.1~ 6000.0S, the acceleration and deceleration time can be set separately | |

| Voltage/Frequency Characteristics |

Determined by the selected V/F curve | ||

| PID | Manually set PID parameters | ||

| Subsidiary Function | V/F curve, low frequency compensation, rated current, current protection limit setting | ||

| High voltage isolation | Electromagnetic coupling, multi-channel fiber optic transmission | ||

| Control power input | AC 220V 2kVA | ||

| Run | Operation | This control (touch screen, cabinet door switch) operation, remote external control operation, host computer operation (optional) | |

| Frequency Given | Touch screen digital given, multi-segment speed given, external control analog signal (DC4~ 20mA) set | ||

| Operating State Output | Relay status output, inverter failure, alarm, operation/stop, etc | ||

| Touch Screen | Input/output voltage, input/output current, set value, fault status of each unit, operating status, transformer status, bus voltage of each unit, etc | ||

| Protection Function | Motor overcurrent, whole machine overvoltage, whole machine undervoltage, unit overcurrent, unit overvoltage, unit overheating, unit input phase loss, fiber optic communication failure, etc | ||

| Environment | Place of Use | Indoor, no corrosive or conductive gases, dust, direct sunlight | |

| Ambient Temperature /Humidity | -10 ° C~ + 40 ° C/20~ 90% RH No condensation | ||

| Vibration | 5M/s2 (below 0.6g) | ||

| Storage Temperature | -20~ + 65 ° C (suitable for short-term storage such as transportation) | ||

| Altitude | 1000 meters, more than 1000 meters can be customized | ||

| Cooling Method and Shell Protection Grade | Forced air cooling/IP31 water cooling/IP40 | ||