Overview

KBS-12 Series Pad-mounted Switchgear Station (Outdoor Ring Main Unit) adopts and incorporates advanced foreign technology. It integrates a 12kV switchgear, circuit breaker, load break switch, current and voltage transformers, 12kV PT, FTU/RTU for switch station automation, CCU for communication and control, 12kV metering and automatic reading devices, UPS power supply, and indicating instruments.

All components are pre-installed, tested, and commissioned inside a movable, sealed, moisture-proof stainless steel enclosure. This design realizes the integration of primary and secondary systems in urban distribution networks, modularizes installation, shortens construction time, and significantly improves the reliability of urban power grid operations.

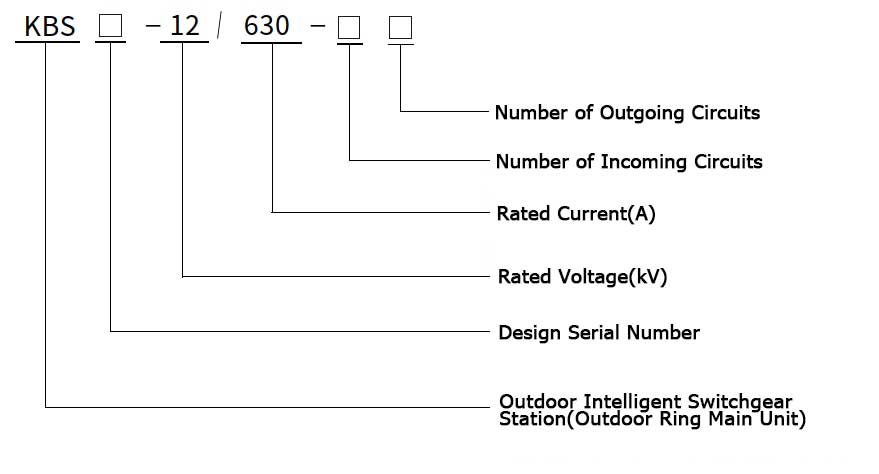

Model and meaning

Technical Specification

| Item | Unit | Technical Requirement | |

| Load Switchgear | Combined Electrical Cabinet | ||

| Rated Voltage | kV | 12 | |

| Rated Frequency | Hz | 50 | |

| Rated Current | A | 630 | 200 |

| Rated Load Breaking Current | 630 | ||

| Rated Short-time Withstand Current (RMS) | kA | 20 | |

| Rated Short-circuit Duration | s | 3 | |

| Rated Peak Withstand Current | kA | 50 / 63 | |

| Closed Loop Breaking Current | A | 630 | |

| Rated Cable Charging Breaking Current | 25 | ||

| Rated No-load Transformer Breaking Current | 16 | ||

| Rated Breaking Transfer Current | 1750 | ||

| Expected Short-circuit Breaking Current of Fuse (RMS) | kA | 63 | |

| Grounding Switch Short-term Withstand Current/Duration | 25kA/s | ||

| Rated Current Breaking Times | Times | ≥200 | |

| Mechanical Life | Times | ≥2000 | |

| Annual Leakage Rate of SF6 Gas | / | No more than 1% | |

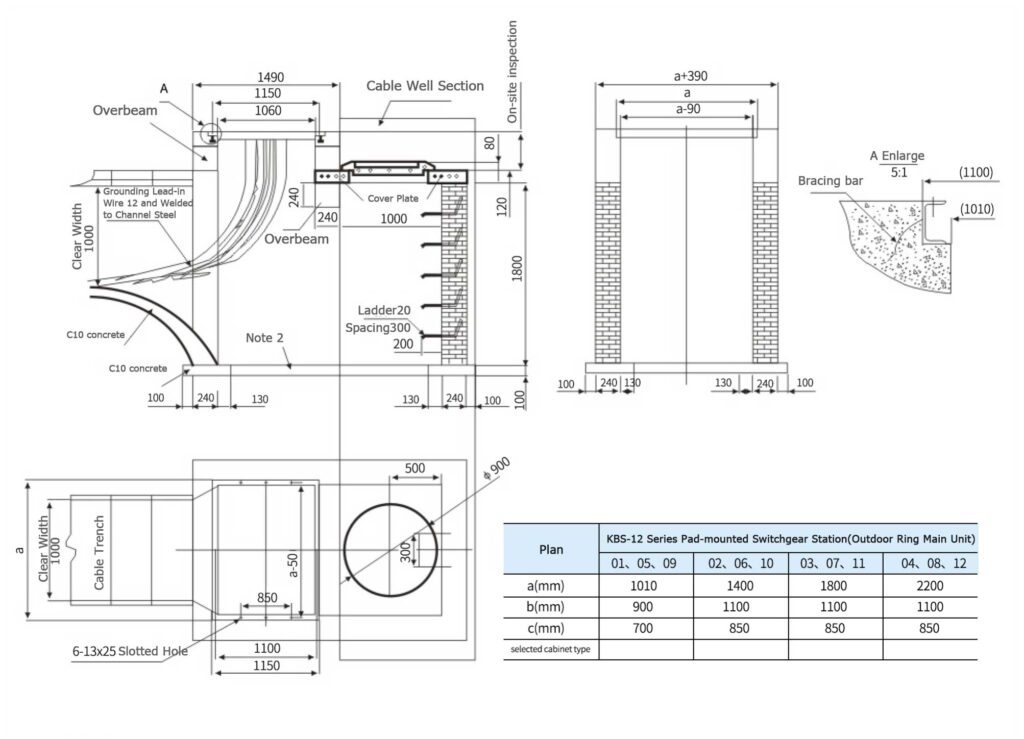

Overall and Installation Dimensions

NOTE:

- Brick walls shall be constructed using M5 cement mortar, with the inside surfaces and the external surfaces above ground finished with 1:2.5 cement mortar plastering.

- If the ground floor is located below the groundwater level, waterproofing treatment shall be applied; otherwise, seepage prevention treatment shall be carried out.

- Lintels shall be fabricated using Φ6 reinforcement bars and C20 concrete.

- The No.8 channel steel base shall be welded and assembled, then subjected to anti-corrosion treatment (the anti-corrosion method to be specified by the user).

- The No.8 channel steel base shall be placed in the foundation recess, fixed with bracing bars and concrete.

- The user may opt not to construct the cable pit (the section shown within the dashed line) depending on the specific site conditions.